Are alumina PCBs compatible with lead-free soldering?

Alumina PCBs Primer

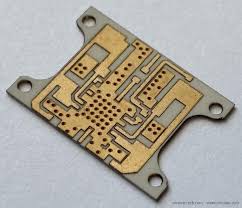

Alumina based PCBs (ceramic printed circuit boards) offer exceptional electrical, thermal and mechanical performance. This makes them the ideal choice for projects with severe electrical, environmental or mechanical requirements where failure can be costly or dangerous. This primer explores alumina pcb compositions, constructions, benefits, applications and key considerations for leveraging them effectively.

Alumina is an aluminum oxide (Al2O3) ceramic with low vapor pressure, high thermal conductivity and chemical resistance. It can be combined with a variety of metal alloys to create hybrid PCBs. For example, alumina can be bonded to flexible Aluminum to provide mechanical flexibility without compromising the high-temperature capabilities of the board. This allows engineers to route high density traces between layers, integrate microwave cavities, build mezzanine modules and deliver other innovations.

The metallization process for creating copper on alumina is different from FR-4 laminates. The copper is plated directly onto the alumina, rather than a dielectric layer. This allows for a thinner overall design and better thermal transfer. It also requires a lower sintering temperature which results in a more cost-effective and durable product.

Are alumina PCBs compatible with lead-free soldering?

Unlike FR-4, alumina does not absorb moisture. This helps prevent outgassing and vapor pressure stresses under high temperatures. It also resists oxidation in harsh environments. Alumina is also less prone to warping or cracking under high heat.

While the alumina substrate offers many advantages, it does not provide as much flexibility as traditional FR-4. It is not suitable for regular flexing, as the alumina is brittle and rigid. It is more suited for applications that require extreme mechanical strength and stability, such as aerospace, military and automotive devices.

Despite its limited flexibility, alumina is suitable for specialized high reliability electronics and hostile environment applications. Its ruggedness under shock, vibration and extreme temperature conditions make it a popular option for radar modules, guidance systems, and radio equipment. Its exceptional durability also makes it a good choice for harsh environment marine navigation systems and radar equipment.

The materials used in alumina PCBs must be carefully selected to ensure that the products meet rigorous quality standards. This is especially important for applications where the circuits are in close contact with human tissue, such as implantable medical devices. This requires alumina ceramics with high purity levels to minimize contaminants and reduce the risk of adverse health effects.

While there are several options for manufacturing alumina pcb, not all manufacturers can produce high-quality boards. This is why it’s important to choose a company that has the experience and expertise necessary to produce reliable boards for your application. When you choose Viasion, you can rest assured that we will use only the best quality materials to create alumina pcbs that will meet your exact specifications. We will also work with you to find a cost-effective solution that will fit your budget. To learn more about our services or to request a quote, please contact us today. We look forward to hearing from you!